We are excited to announce the entry of Pactur into the new sector of vacuum packaging machines. Vacuum packaging is one of the most effective and safest methods for food preservation. Thanks to this technology, it is possible to preserve the freshness and quality of food products for longer periods, reducing waste and improving efficiency.

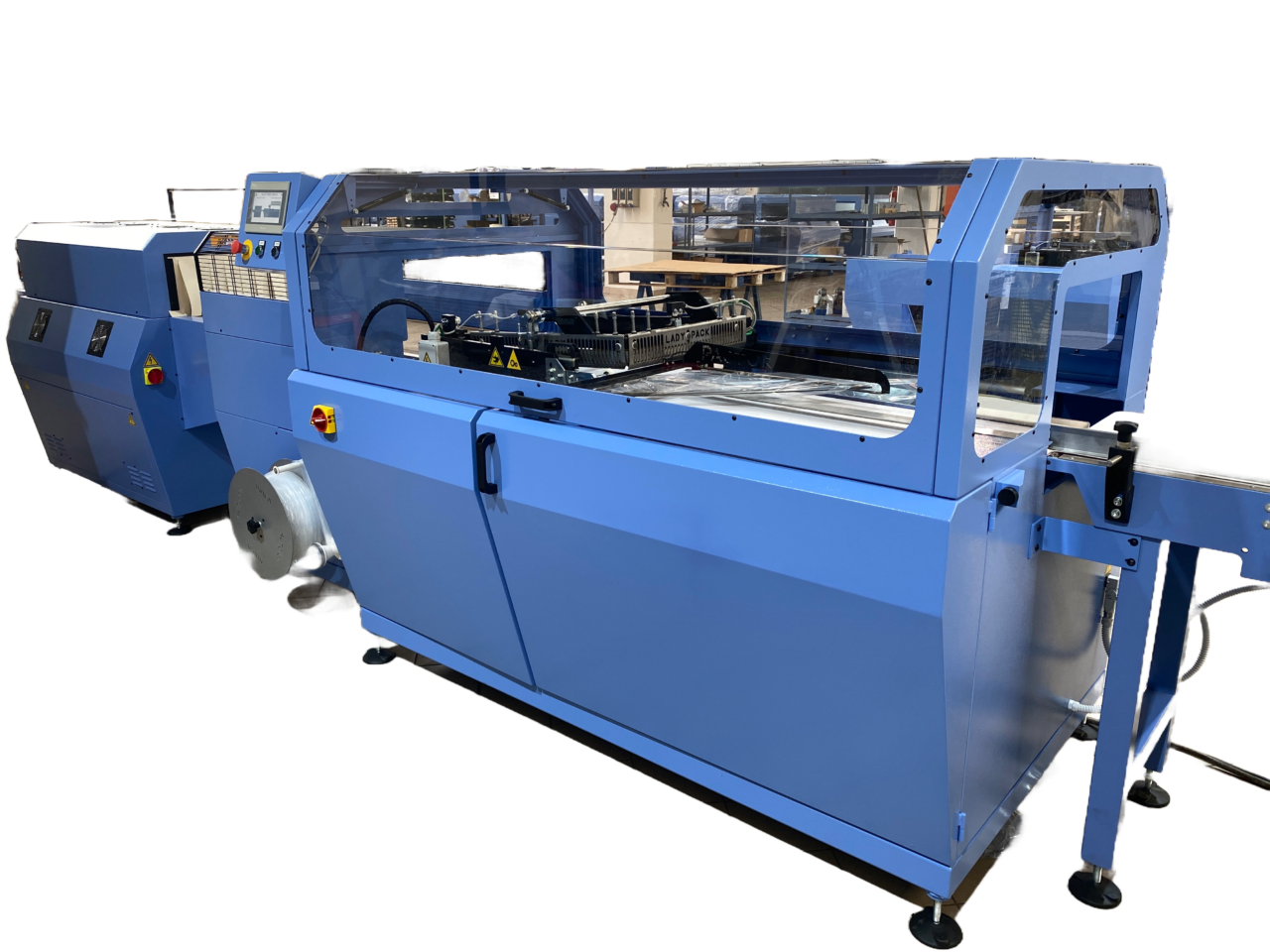

Our chamber vacuum machine models, precisely designed and meticulously detailed, are ideal for every need, from small catering businesses to large food packaging companies. They are all countertop models, making them compact and easy to place in any work environment. Different sealing bar sizes are available, including 265 mm, 318 mm, and 450 mm, to accommodate various packaging requirements.

The structure of our vacuum machines is made of stainless steel, meeting all food industry requirements. This ensures durability, hygiene, and compliance with industry standards. An important detail: all models are affordably priced, combining high quality and convenience. This makes them accessible for businesses of all sizes, offering a reliable solution without compromising on performance.

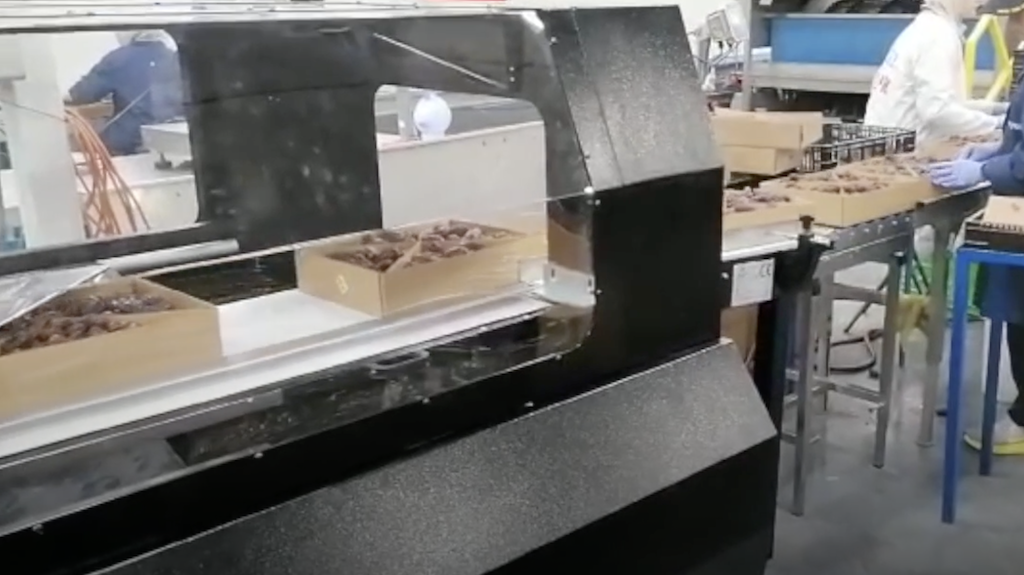

In addition to the vacuum packaging function, we offer specific programs for vacuum marinating and food preparation for sous-vide cooking. Vacuum marinating allows flavors to penetrate more deeply and quickly into the food, enhancing the taste and quality. The sous-vide preparation ensures even cooking at precise temperatures, providing a professional cooking experience.

Furthermore, some models also allow label printing with all essential information about the packaged product, offering a complete and professional food packaging management system. This feature is particularly useful for tracking inventory, ensuring compliance with labeling regulations, and providing consumers with detailed product information.

Pactur is committed to promoting packaging sustainability. Our vacuum packaging machines are designed to minimize waste and extend the shelf life of products, contributing to a reduction in food waste. By adopting our bakery packaging machines and other vacuum packaging solutions, businesses can achieve greater efficiency and sustainability in their operations.

In conclusion, Pactur’s entry into the vacuum packaging sector marks a significant step forward in offering advanced, reliable, and sustainable packaging solutions. Our chamber vacuum machine models are a testament to our dedication to quality, innovation, and environmental responsibility.

TECHNICAL FEATURES

| Power supply | 120V 230V |

| Phase | 1 Ph |

| MAX power installed | 0,36 Kw (230V) 0,4 Kw (120V) |

| Maximum current | 1,56 A (230V) 3,3 A (120V) |

| Vacuum pump | 4 m3 (DVP) |

| Dimensions of the sealing bar | 265 mm |

| Available chamber dimensions (Tank+lid) | 270×154 h.179 mm |

| Machine dimensions (lid open) | 325×425 h.510 mm |

| Machine dimensions (lid closed) | 325×425 h.240 mm |

| Package sizes | 525×430 h.300 mm |

| Machine weight (Net/Gross) | 24/27 kg |

Contact us for more details

see also PACTUR.IT