Pactur at the Tokyo Packaging Fair

Pactur brought to Tokyo the latest Ladypack innovations for shrink wrapping:

energy efficiency, touch interface and Made in Italy quality, in collaboration with the Japanese partner M Technologies.

Innovation and Sustainability

At the Tokyo Packaging Fair, Pactur presented its new manual, semi-automatic and automatic shrink wrapping machines, equipped with touch screen panels, energy-saving systems and ergonomic design.

The goal is to improve productivity and reduce energy consumption while maintaining the outstanding build quality

that characterizes the Ladypack brand.

Why Japan Values Made in Italy

Mechanical precision, attention to detail and long-lasting performance are the qualities that the Japanese market

recognizes in Pactur. President Paola Dozza emphasized how cooperation with local distributors

allows Pactur to offer timely installations, operator training and after-sales support.

Partnership with M Technologies

Pactur’s participation took place in collaboration with

M Technologies, a Japanese distributor specialized in promoting Ladypack machines throughout the Japanese market.

The joint booth attracted numerous visitors from the food, cosmetic and industrial sectors.

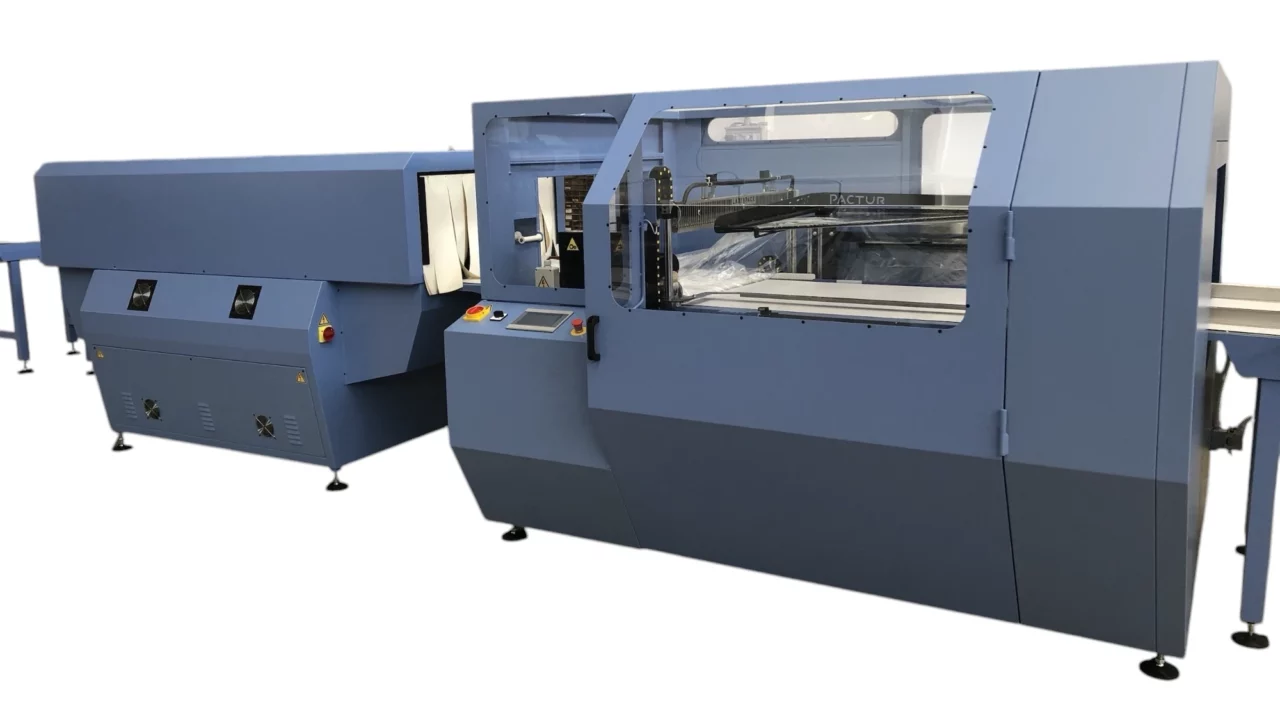

Machines on Display

Automatic L-sealers with Tunnel

Compact solutions with in-line integration, quick format change and digital control of sealing and shrink parameters.

Ideal for continuous production cycles and high-quality packaging results.

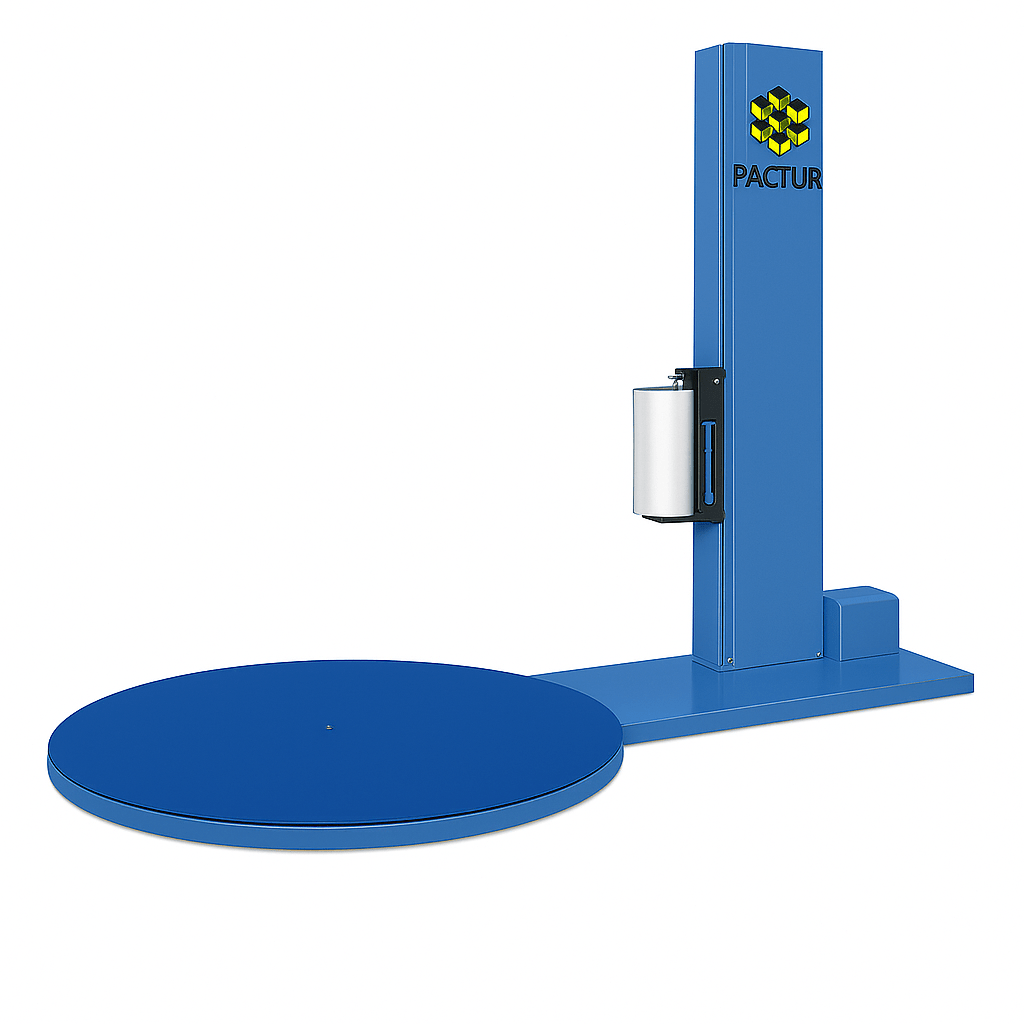

Chamber and L-Sealers

Versatile models for small and medium production runs, perfect for laboratories and pilot lines.

Ladypack machines combine compact design, ease of use and excellent film shrink results.

FAQ

Can customers test their products?

Yes, Pactur performs shrink tests and material analysis to identify the most suitable solution.

Do you provide installation and training in Japan?

Yes, through our local partner M Technologies,

which manages logistics, training and technical support.

Which industries do you mainly serve?

Food, bakery, cosmetics, publishing, components and promotional multipacks.

Contact the Pactur Team

Would you like more information about our shrink wrapping machines or to book a live demo?

Our technical and sales team is ready to assist you.

📩 Email:

pactur@pactur.com

☎️ Phone:

(+39) 051 616 7287

💬 WhatsApp:

+39 335 8418141

Or fill in the contact form to be reached by one of our specialists: