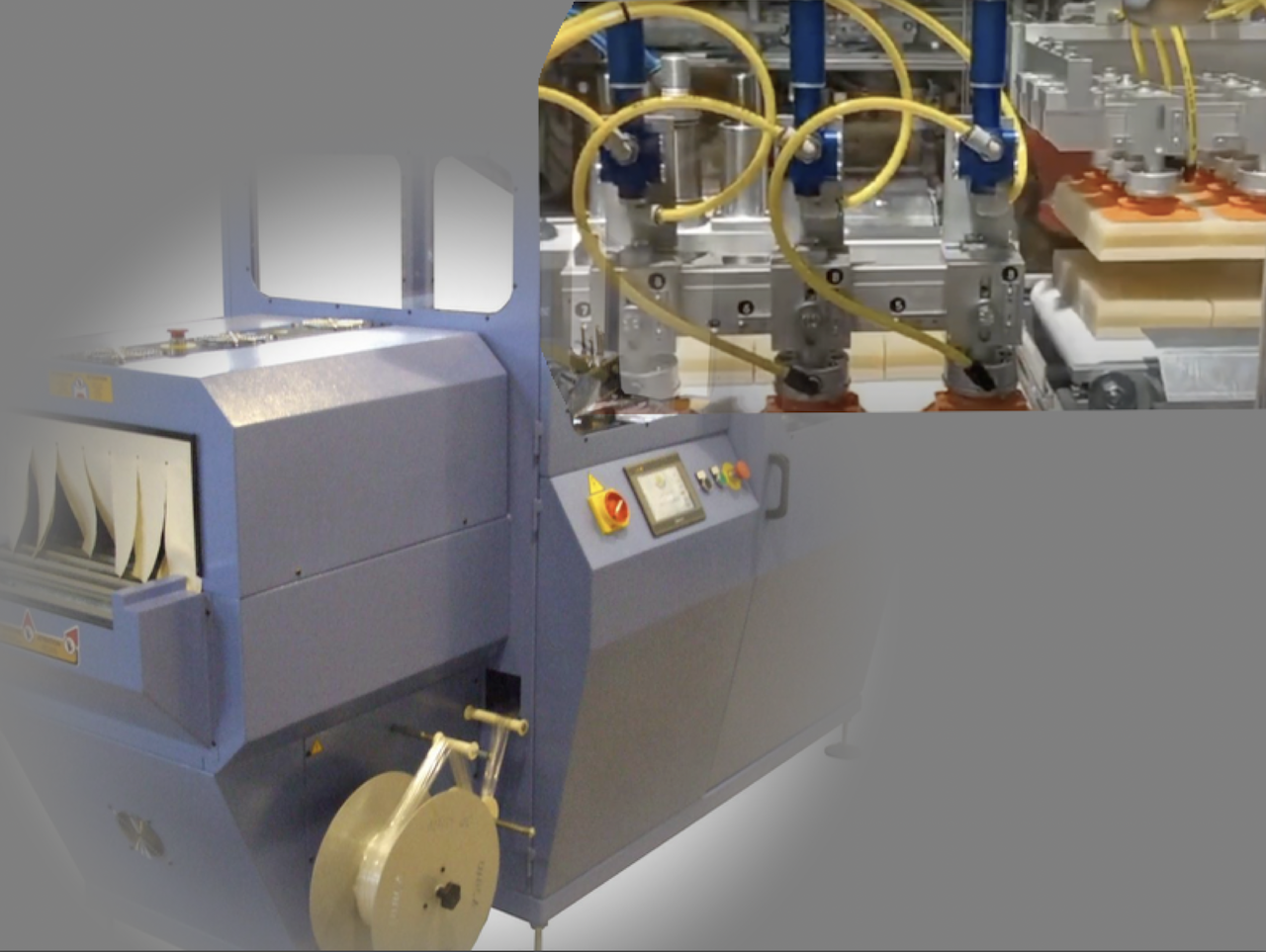

AUTO 40 UNICA FOR SOAP PACKAGING LOADED WITH PICK & PLACE

Shrink machines represent an important step in the industrial packaging process, used to apply thermoplastic films around products or packages, which are then heated to shrink and adhere to the contents. The introduction of robotic lines in this context can bring numerous advantages. (AUTO 40 UNICA FOR SOAP PACKAGING LOADED WITH PICK & PLACE).

Robotic lines for feeding shrink-wrapping machines offer various benefits in terms of efficiency and precision. Robots can be programmed to handle loading and unloading of packaged products quickly and accurately, reducing machine downtime and increasing overall productivity.

Additionally, robotic systems can be equipped with advanced sensors and cameras to precisely detect the position and orientation of products, allowing for optimal positioning within shrink machines. This precision helps reduce waste and improve package quality.

Flexibility represents another advantage of robotic lines for feeding shrink-wrapping machines. Robots can be easily repurposed and programmed to handle different types of products or packages without the need to completely change the system, allowing companies to quickly adapt to changes in market demand.

However, the implementation of these robotic lines requires careful design and integration into the existing production process. Compatibility between robots and shrink machines must be considered, as well as staff training to effectively operate and maintain these automated systems.

In conclusion, the use of robotic lines to feed shrink machines offers an efficient, precise and flexible solution to optimize the industrial packaging process. If properly implemented, these solutions can lead to increased productivity and quality, allowing companies to maintain a competitive position in the market.

AUTO 40 UNICA FOR SOAP PACKAGING LOADED WITH PICK & PLACE